We are Manufacturer, Supplier, Exporter of Offline Industrial Oil Filtration System, Aluminium Die Casting Components From Pune, Maharashtra, India

Company Profile

The company : Bhagyashree Accessories Pvt. Ltd. was incorporated in 1994. The company is at

Narhe Industrial Area located off Mumbai-Bangalore by-pass highway in Pune,

Maharashtra, INDIA.

A Private Limited Company established under Companies Act.

• Privately held shares in three directors:

• Mr. Satyajit Suresh Chitale –Managing Director

• Mr. Suresh Atmaram Chitale- Director

• Mr. Ajinkya Vasant Kulkarni- Director

Authorized Share Capital :

INR 10 Lakh

Manufacturing and Research Facilities :

The company is equipped with modern CNC / VMC machining technology for production of centrifuge components. Other quality machining is done on high precision machines like cylindrical grinder, radial drilling machines, Capstan lathes etc. Over last twenty years, operating persons from our company have developed significant know-how about production support aids like jigs, fixtures and tooling. Development of production support aids is now done in-house as per requirement under the guidance of our technicians.

Inspection & Gaging Facility :

Equipped with

• Height Masters

• Digital measuring instruments

• Surface Roughness Tester

• Rockwell Hardness Tester

• Magna-flux Crack Detection for ferrous components

• Rubber Hardness Testing

• Millipore Test Facility

• Calibration and Gage management conforming to QMS requirements

• MSA is a standard practice

Captive Deep Draw Press Shop :

• Equipped with 100 ton capacity Double Action Deep Draw press.

• Bolster Size 600x600mm

• Cushion pressure 40 ton

• Can draw upto 3 mm thick MS EDD sheet upto 270 mm draw length

• Capacity:

> 2500 components per month for large jobs

> Upto 8000 components per month for small job

• Equipped with Press Break, Circle shearing, trimming and other forming operation equipments

CNC Machining Shop :

• No of CNC Lathes: 3 Nos

• No of VMC: 2 Nos

• VMC with B Axis: 1 Nos

• Dimensional Accuracy Achieved: 20 micron

• Process Capability ( general trend) :

> Cp>2.0

> Cpk>1.66

• Operates in 2 shifts

• OEE ( General Trend) > 72%

Important Facts and Figures :

• Company Established in September 1994

• Sales Turnover FY2018-19 (Unaudited) INR 45.6 Million

• Total Employee Strength: 53

> Engineering & Management : 4

> Design : 2

> Quality : 6

> Purchasing : 2

> Sales & Business Development : 2

> Production : 37

• Sales Pattern FY2018-19

> Sales to Engine or System OEM’s: 68%

> Sales of Industrial Systems: 11%

> System and component Sales ( Export): 21%

• Sales and Distribution Channels

> Domestic sales are centrally managed by company. We are in talks with few

parties to be appointed as distributors

> Export Sales through re-sellers and co-branding partners in USA,

EU ( The Netherlands), Australia and UAE

Manufacturing Capability :

• Total Factory Area: 8000 sq.ft

> RCC 2 Storied Building Self Owned

• Activities under one roof :

> Aluminium Gravity Die Casting Foundry

> Deep Drawn Sheet metal press shop

> CNC machining facility

> Assembly and Testing Facility

> Design and Engineering with CAD facility

Captive Foundry : The company has set up an Aluminum die casting foundry in August 2005. The

Company now makes all Aluminum gravity die castings for its captive requirement. Present Pouring Capacity is 3 tons per month, being increased to 10 tons per month this year.

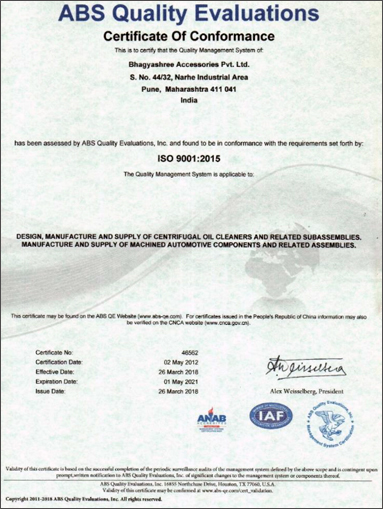

Quality Standards : The company has in-house testing facilities with test equipments like Magnetic Crack detection, Hardness Tester, Slip gauges, and modern digital measuring instruments. The company has developed testing rigs for centrifuges to measure performance of each centrifuge manufactured. The company has access to approved laboratories where material testing and oil testing is done. Testing of incoming materials is a regular practice for each lot. The quality systems in the company are ISO9000 compliant and the company is certified with ISO 9001:2008 QMS certification by ABS QE, Houston, USA. Major inputs that go into the centrifuge assembly are made 100% in-house; this ensures highest quality of the products manufactured by the company.

Aluminium Gravity Die Casting Foundry :

• Total Casting Capacity : 4 ton per month

• Casting Range : 200 gram to 13 kg

• Equipped with Nitrogen purging de-gassing system; master alloy treatment practice

• Alloys Casted : Aluminium-silicon-copper alloys

• Planned Expansion : to cast brass castings

Dynamic Balancing Facility :

• No of Machines

> 0-3 kg Capacity: 1 No.s ( Schenck Rotec Make)

> 0.3 to 10 kg: 1 No.s ( FIE Make)

• Accuracy Grade Achievable conforming to 2.5g as per ISO1940

• Balancing correction by weight addition or weight removal – both possible

Taxation Details :

PAN No : AAACB7127Q

ECC No : AAACB7127Q-XM001

MVAT TIN : 27030019186V

CST TIN : 27030019186C

ESIC Code : 33-12717-67

EPF Code : MH/PUN/301837

Certifications & Registrations :

1. ISO9001:2008 Certified by ABS-QE, Houston, Texas, USA

1

1 2

2 3

3 4

4